CNC Machining Centers

Evolution Vertical CNC

The EVOLUTION series offer unique patent-pending solutions for complete processing of your workpieces. Distinguished by well-thought-through industrial design and extremely stable layout.

Unique in its class, the EVOLUTION 7405 4mat offers absolutely precise edge routing on all four workpiece edges and thus complete formatting for panel material.

The technical data for the Evolution series speaks for itself: Workpieces with height up to 920 mm and unlimited length can be processed with the smallest possible space requirements. Material thicknesses of 8 to 70 mm make the vertical machining centers from HOLZ-HER all-round machines for producing everything from drawers to body parts, furniture fronts and rear walls; in short complete machining of all your products. Short cycling times and extreme precision, because workpieces with lengths up to 1,500 mm can be machined without reclamping. The solid design of the EVOLUTION series guarantees you maximum machining quality.

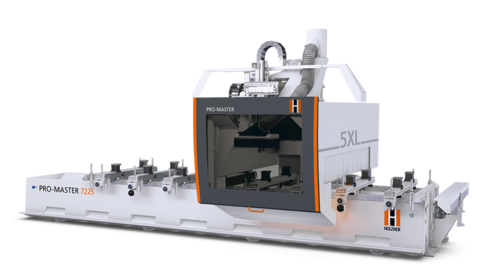

Pro-Master Series

CNC Machining Solutions for solid wood, panels and composite material to make you even more potent in competition.

CNC Machining Solutions for solid wood, panels and composite material to make you even more potent in competition.

Investments in state-of-the-art CNC machines are worthwhile. Furniture and components even with complex designs can be produced economically and precisely. Latest generation control technology, drives and software ensure virtually unlimited possibilities. CNC machines designed for efficient and accurate machining of solid wood, panels, windows and doors, composite material and aerospace.

Awake the potential of the CNC machines of the PRO-MASTER series. The CNC-machining centres are distinguished by their solid design and maximum flexibility. Every PRO-MASTER is preconfigured at the factory for your special range of applications to ensure that you can always count on its comprehensive standard equipment.

The 5-axis PRO-MASTER CNC machines offer state-of-the-art CNC technology for cutting 3D contours. The software provided with the machine provides an open interface for transfer of complex 3D data via postprocessors from leading CAD / CAM software providers. The 5-axis PRO-MASTER series provides extremely short feed and acceleration values. The unique 17 kW cutting spindle with PRO-TORQUE technology turns the HOLZ-HER 5-axis CNC machine into true power packages for machining operations with highest processing quality. Learn More

Nesting Machining Centers

Time savings in production with HOLZ-HER nesting technology

Time savings in production with HOLZ-HER nesting technology

HOLZ-HER has its brand new nesting technology on the market. Get all information about the innovative nesting CNC machining centers DYNESTIC 7532, DYNESTIC 7507 and DYNESTIC 7505. All three machining centers have a high automation capability and are available in different equipment variants.

HOLZ-HER's nesting technology ensures efficient formatting and drilling on one machine. Here the panel is held by large-surface vacuum on a wear plate. The great advantage of this production method is production of exactly formatted workpieces, already provided with groove or rebate in the rear wall and all required vertical holes for shelves, connectors, etc. Above all the entire process is accomplished without additional handling work and is therefore extremely efficient in terms of time and resources.

The essential prerequisite for nesting is, however, that the proper software be fully integrated into the machining process. Here HOLZ-HER offers a free-form solution for stairs and frame constructions as well as a purely rectangular nesting feature. With its versatile import possibilities for highly differing nesting modules as well as complete graphic control surface and barcode interface, the machine is optimized for comprehensive applications.

HOLZ-HER's nesting CNC machining centers allow cut-optimized machining and cutting on panel materials. The automation components for material handling makes the DYNESTIC series even more efficient. Learn More